Home / Services / Operations / Management Systems / CQI-23 Moulding System Assessment

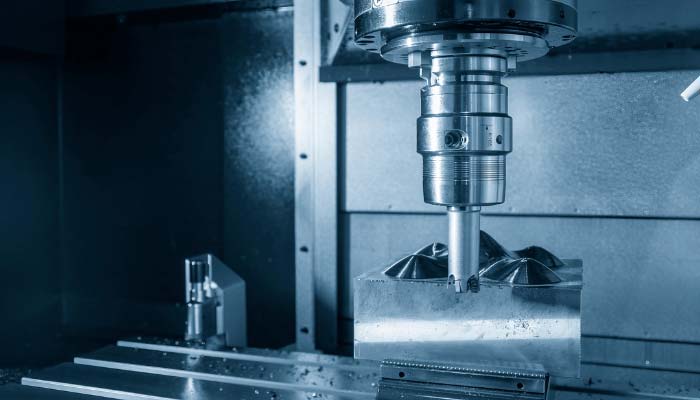

Optimizing Molding Excellence with CQI-23 Compliance

IMPROV specializes in helping organizations adopt and implement the CQI-23 Molding System Assessment framework. This industry-specific standard ensures the consistency, quality, and reliability of molding processes, crucial for manufacturing high-precision components across various sectors.

The CQI-23 standard provides a structured methodology to assess and enhance molding systems, focusing on process controls, defect minimization, and adherence to customer requirements. It applies to injection molding, compression molding, transfer moulding, and other advanced molding processes.

Core Focus Areas of CQI-23

- Process Qualification and Validation: Develop molding processes that ensure repeatability and reliability.

- Equipment Maintenance: Implement preventive maintenance schedules to minimize equipment downtime and maintain operational consistency.

- Material Management: Control the quality of raw materials, additives, and environmental factors affecting the molding process.

- Operator Competency: Train personnel in best practices and advanced techniques for molding operations.

- Defect Detection and Analysis: Leverage root cause analysis to address and prevent quality issues.

Industries Leveraging CQI-23

- Automotive Components

- Consumer Electronics

- Aerospace and Defense

- Medical Devices

- Industrial Equipment

Key Benefits of CQI-23 Implementation

Improved Product Quality

Ensure high precision and consistency in moulded components, meeting stringent industry requirements.

Process Optimization

Achieve operational efficiency by reducing material waste, cycle times, and process variability.

Compliance with Customer Expectations

Deliver products that align with global standards and client specifications

Defect Reduction

Identify and mitigate common molding defects such as warping, flash, or sink marks through robust controls.

Enhanced Operational Efficiency

Streamline processes to reduce downtime and improve productivity.

How We Help

Process Evaluation

We assess your existing moulding operations to identify improvement opportunities and align them with CQI-23 standards.

Customized Implementation

Tailored solutions designed to meet the unique needs of your business and operational goals.

Skill Development

Training programs for employees to enhance their proficiency in moulding system operations.

Audit Readiness

Support for internal and external audits, ensuring compliance and certification readiness.

Continuous Monitoring and Improvement

Set up mechanisms for ongoing quality monitoring and process refinement.

Our Expertise

- Deep Industry Expertise: Proven experience in molding systems and process assessments across diverse industries.

- Comprehensive Solutions: End-to-end support from initial assessment to full implementation and beyond.

- Customer-Centric Approach: Strategies designed to align with your unique business objectives and challenges.

- Commitment to Excellence: Dedicated to delivering measurable improvements in quality, efficiency, and compliance.

Transform Your Molding Operations with IMPROV

Achieve world-class molding standards with CQI-23 implementation and support from IMPROV.